Electric Motor

Whitelegg’s long involvement with electric motor manufacturing, test and repair has enabled the company to provide a comprehensive range of machinery, instruments, tools and consumables for use in all aspects of the industry. Sales are made worldwide with spares and support readily available.

Motor Monitoring Equipment

We offer techniques for both online process motor testing, as well as offline functional bench testing. Our latest Schleich range also offers versatile testing in the production line environment as well as for consumer goods, such as cookers, luminaries etc. The latest intuitive software ensures fast and accurate results.

Electric Motor Monitoring and Testing

Latest research suggests over 50% of UK energy is consumed by electric motors. The majority of these are in business and industry. Many are running in critical situations such as power generation, production processes, pumping and transport.

Inherent faults may not be obvious but, over time, failure can be catastrophic. Additionally, incorrectly rated motors for the task assigned or bad maintenance will result in wasted energy and higher costs.

We have a major involvement with the supply of advanced motor monitoring and diagnostic instruments.

View Electric Motor Repair monitoring and testing equipmentElectric Motor Rewind

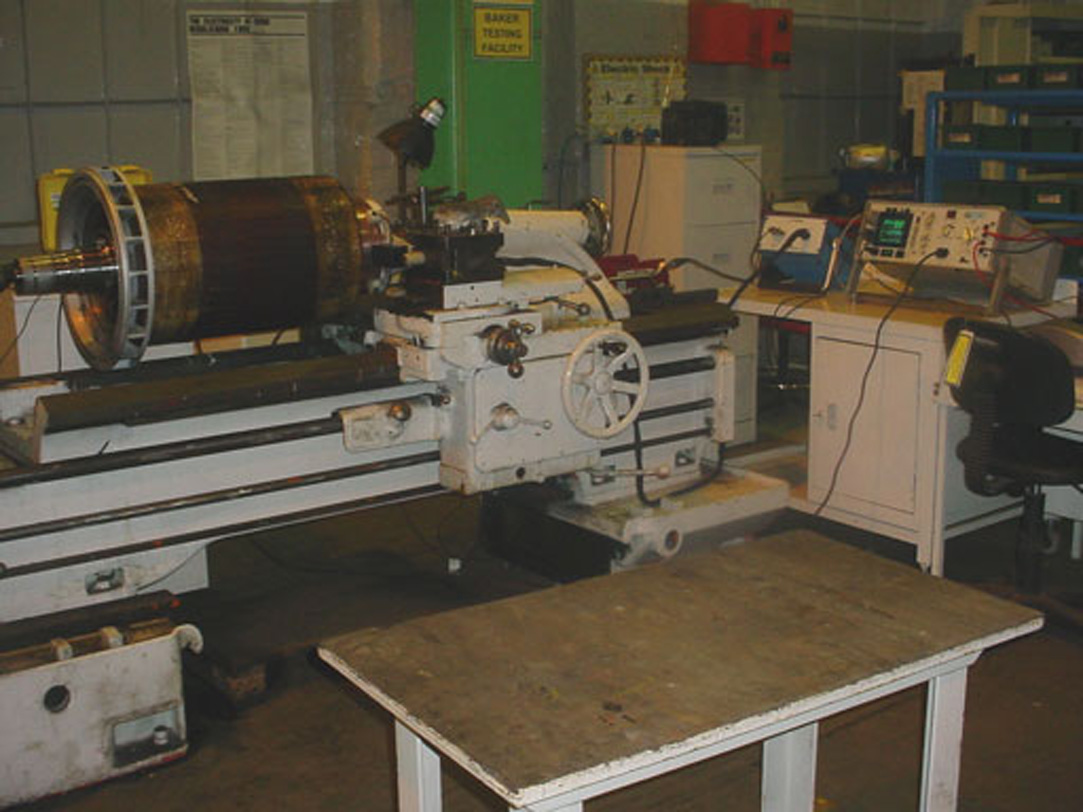

For every process in the rewinding of electric motors, Whitelegg offer equipment to improve efficiency, reduce the possibility of damage to the motor and decrease the time taken to effect the repair.

For example our specialist hydraulic coil-pulling machines are the only ones on the market that will pull the winding against the back of the slot. This speeds up the process and drastically reduces the possibility of damage to the stator laminations. Small details like these result in real benefits to the end user and as a consequence increase the profitability of the electric motor repair.

View our range of Electric Motor Rewind machines and accessories

Electric Motor Repair

We offer a full range of equipment from consumable items such as commutator saw blades and wire stripping blades, through to different hand tools for every stage in the electric motor rewind process and including coil winding machinery, impregnation, curing and electric motor testing.

Whitelegg Electric Motor Repair Brochure 2014

- Electric Motor Repair Products

- Dismantling and Cleaning

- Coil Cut off and Extraction

- Coil Winding Machines

- Coil Winding Accessories

- Rewind Accessories

- Insulation equipment

- Impregnation and Curing

- Commutator Equipment

- Test Equipment

- High Voltage Coil Manufacture